em-boss-ing (em-baws-ing)

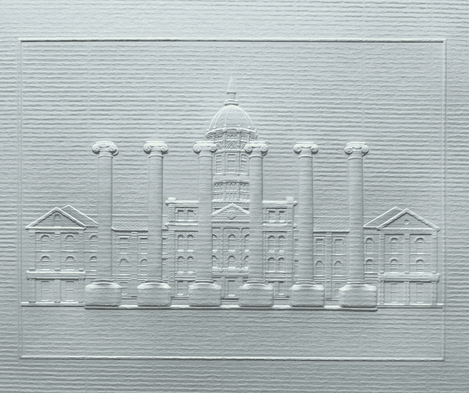

verb . . . and debossing either raises or depresses designs into paper by stretching and shaping the paper fibers with pressure and heat. You can achieve an elegant embossed effect with one level of etching creating a flat image with either a beveled or rounded edge, or a sculptured look with many levels of etching. The more elaborate the design and etching, the greater the cost of making the engraving or die. The design and the paper stock will determine effectiveness. An image that is “raised only” is referred to as “blind” embossing. Embossing can also be done to register with either a printed or stamped image.

KEYS TO SUCCESS

EMBOSSING DIES consult our pre-production department before furnishing embossing dies.

E-MAIL OR FAX preliminary artwork to us at the initial design phase for suggestions. We can anticipate small changes that will help satisfy your customer.

COPPER DIES should be used for jobs requiring fine detail, quantities in excess of 1.000 or embossing on heavily textured paper and with a high likelihood of repeat.

EDGES should be specified as round, beveled, faceted or snap.

FONT SIZES LESS THAN 10 PT. should be avoided. Also avoid tight kerning or condensed type.

DEPTH as a general rule we cannot satisfactorily emboss an area any narrower than the thickness of the paper stock being embossed.

COVER STOCKS work best to achieve maximum depth of emboss.

MARKED SHEETS showing position should accompany your press sheets. MARKED PRESS SHEETS, CONSTRUCTED BLUELINES, OR PREVIOUS SAMPLES showing desired construction should also accompany your order.

SPECIFICATIONS: Gripper: 5/8″ Minimum Sheet Size: 6×7 Maximum Sheet Size: 31.5×44 Maximum Image Area: 31×44 Paper Weight: 100# text weight to 20 pt. Caliper Board

Need more information? Call our office at 660.263.3620 and speak with one our CSRs, or email your CSR directly.

You may also send an estimate directly to our queue at estimate@theprecisionline.com, or request an estimate here on our website.